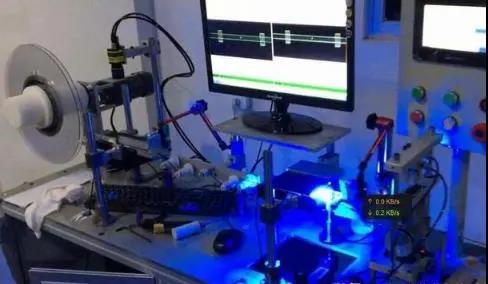

With the rapid development of machine vision and industrial automation, the subtle surface defects of various components have a greater and greater impact on the performance of components. How to better detect product surface defects has also been put forward. Machine vision system can partially replace human vision, but there are still many challenges in using machine vision system in some complex scenes.

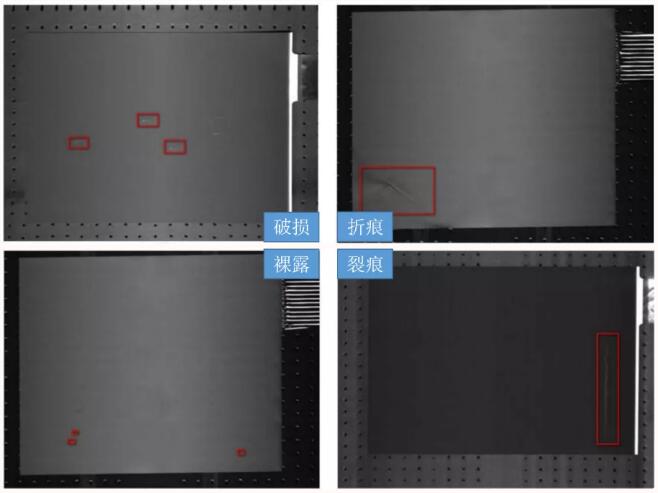

Traditional vision algorithms have some limitations. For example, the defect features in the image may be very diverse, so it must be judged by the engineer and repeated experiments to determine which functions can be used to best identify the defects. Because programming is difficult to cover all defect features, traditional vision algorithms usually encounter high false positive rate. The method based on deep learning can alleviate many such problems and detect the defects that may not be detected by traditional algorithms. Therefore, the deep learning method can supplement the existing traditional algorithms, so that the whole solution is easier to operate and more accurate.

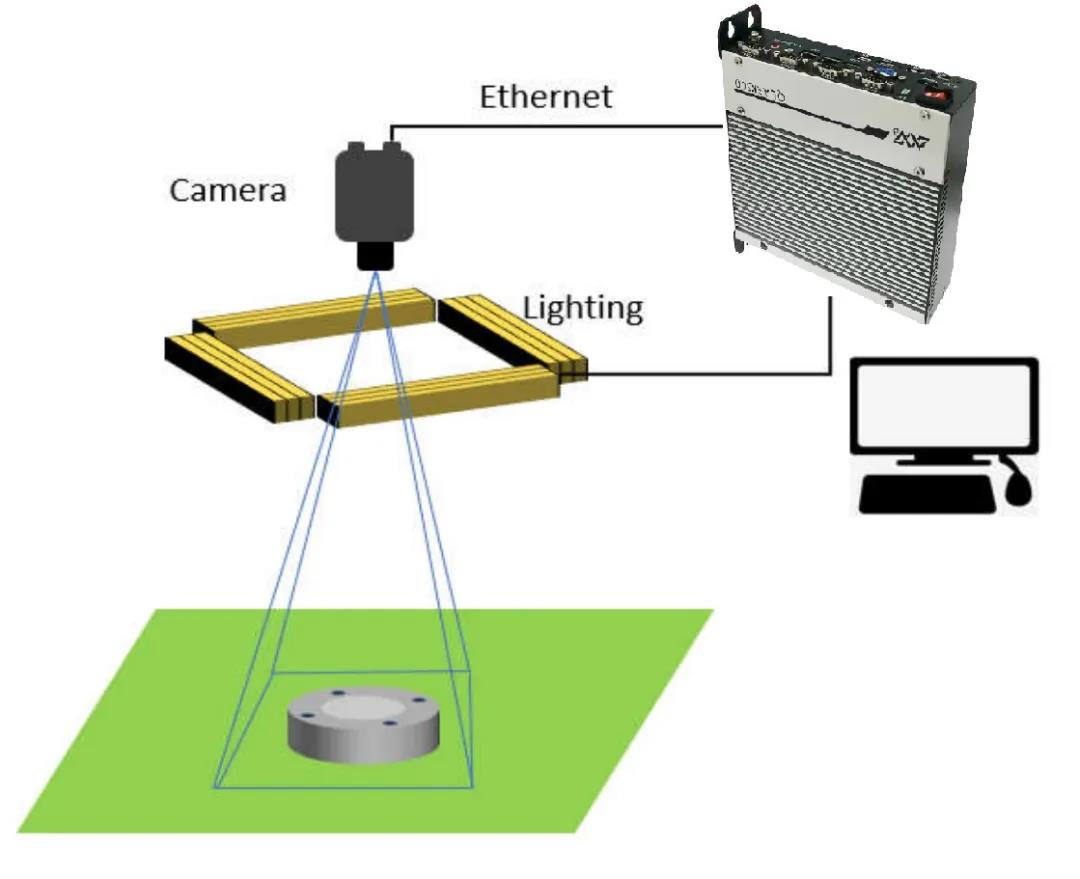

The application of deep learning includes model training and reasoning. The hardware configuration must be considered. The hardware configuration should be able to run the neural network model while meeting the real-time performance requirements of the equipment and the rhythm of the production line. Quark-300 series is a mature solution, equipped with Intel 5-10 generation core processor. It is suitable for applications in MV and AI industrial interference environment, and supports gigabit network or USB3.0 as camera input.

机器视觉系统中,工控机作为整个检测系统的“大脑”,所需配置的工控机性能上具有更高的要求。阿诺威·华北科技作为专注于工控机系统的领导厂商,基于用户需求推出的QUARK-300系列非常适用于机器视觉检测应用场景。

Main features of quark300 series

·High performance: multiple processors on different platforms can be dual core or 4-core core processors;

·Up to 32GB DDR4 memory;····Integrated ® Intel ® HD graphics for AI accelerators;

·Multi interface support: Ethernet, USB3.0, USB2.0 and RS232 & rs485uart;

·Fan less embedded design support.